BENEFITS OF LASER WELDING

- Minimum heat input, resulting in minimal distortion of the component;

- Consistent, repeatable welds;

- Small heat affected zone (HAZ);

- Narrow weld bead with good cosmetic appearance;

- High strength welds;

- Easily automated;

- High degree of accuracy and control;

- Ability to weld dissimilar materials;

- Flexibility of beam manipulation, including fiber-optic delivery;

- Ability to weld in areas difficult to reach with other techniques;

- Often faster than other techniques with greater throughput;

Prototype Capabilities

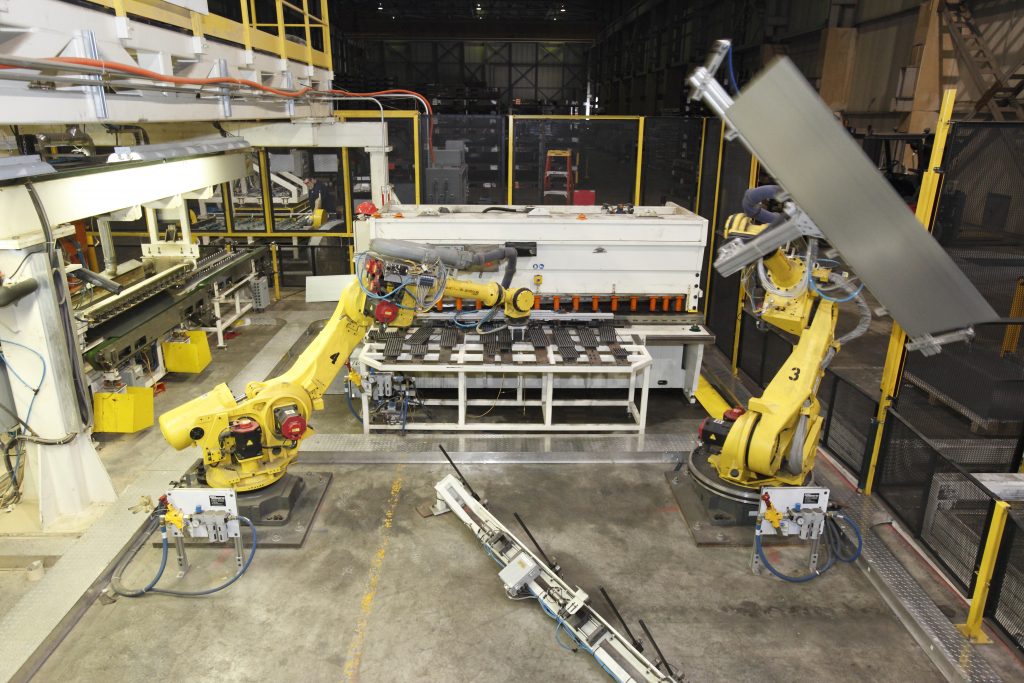

Semi Automated Linear Welding Cell

- IPG Fiber Laser –5KW

- Linear Weld Capability – 80”

- In-line TEMATE Ultrasonic NDT Weld Inspection

- 4 – R2000 RJ3 Fanuc Robots

- In-line shearing – Cincinnati’s

- In-line notching capabilities

- In-line part dimpling

Manual Linear Welding Cell

- Rofin HF880 CO2 Laser –8KW

- Linear Weld Capability – 80”

- Manual In-line shearing – Cincinnati’s

- Manual In-line part dimpling

Automated Shear Cell

- 2 Cincinnati Shears / R2000 RJ3 Fanuc Robot